by Laurent Perra, Director of Sustainability EMEAI

Each year, more than 6 million vehicles in Europe reach the end of their useful lives. While these end-of-life vehicles, or ELVs, are frequently recycled, the European Commission has proposed stronger rules to help achieve circularity, resource efficiency and environmental protection.

If passed, the Regulation would replace existing EU laws and Directives. And because it is a Regulation, it would be legally binding in each EU member state.

Here is what auto industry professionals need to know.

The proposal is designed to cover the complete lifespan of a vehicle, from design to disposal. It sets rules on materials usage, establishes vehicle registration systems to ensure collection compliance of ELVs and requires recovery and recycling of materials found in autos. And it strengthens Extended Producer Responsibility, or ERP, to ensure cooperation along the supply chain.

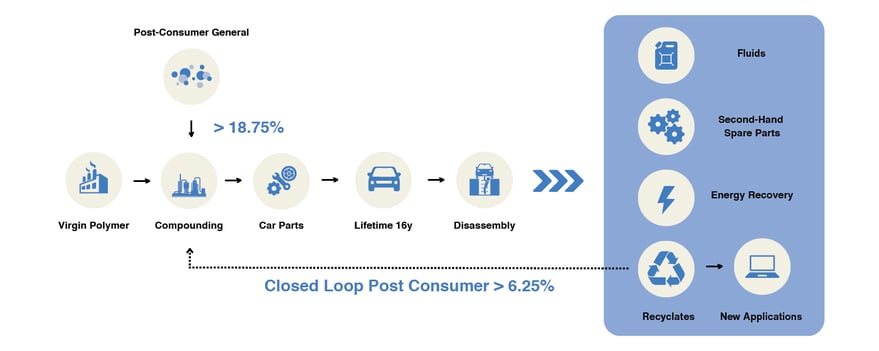

The one key requirement is that vehicles must be made using an average of 25% of post-consumer recycled materials, including 6.25% derived from closed-loop feedstock.

The stronger mandates create a number of significant implications for material suppliers, automakers and recyclers.

Manufacturers are going to have to examine their processes from beginning to end. With a plan in place and the right suppliers lined up, they will be able to achieve their sustainability goals without sacrificing the qualities their customers depend on.

Automakers may need to change their design and production processes to ensure vehicles can be dismantled more easily. They also will need to include clear instructions on how to remove ELV parts. The proposal states that at least 25% of the plastics used in new vehicles must be sourced from post-consumer recycled (PCR) materials, and 25% of that feedstock (i.e. 6.25% overall) must be circular or closed-loop.

This requires a closer collaboration across the circular value chain. The challenge for automakers will be finding high-quality PCR materials that meet their exacting specifications without sacrificing quality.

Next steps

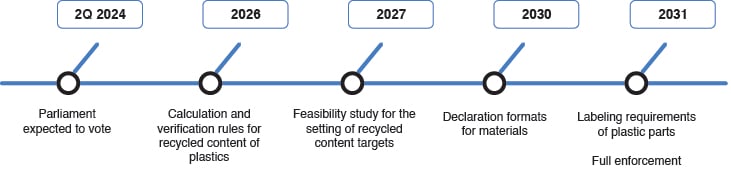

The EU Parliament is expected to vote on the final text in spring of 2024. Rules for recycled plastic content are to be calculated and verified by end of 2026, followed by a feasibility study for setting the recycled content target in 2027 and a declaration of material formats in 2030. Full enforcement of the Regulation is expected to begin in 2031.

How Ascend can help

Ascend has anticipated the transition towards ELV circularity and can effectively support automotive customers as well as recyclers based on experience gained in the circular economy.

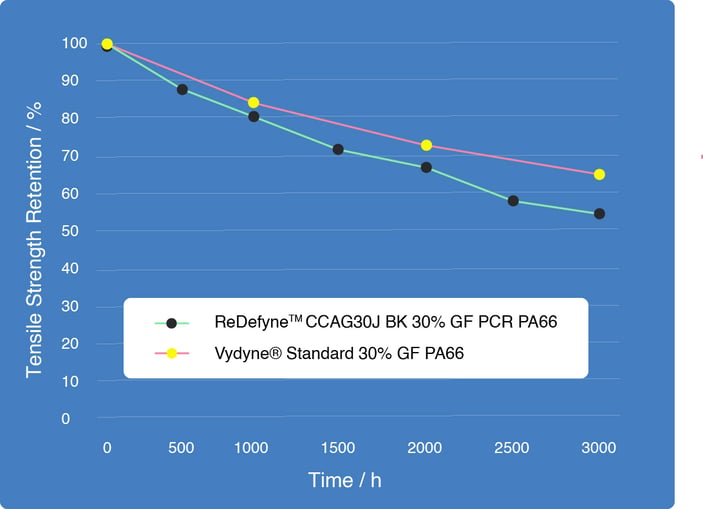

Not all recycled materials are equal. The success of our ReDefyne™ sustainable PA6 and PA66 offerings has shown that circularity can be achieved using PCR-based materials that meet performance requirements.

The ReDefyne portfolio includes pre- and post-consumer content depending on performance and sustainability needs, and comes in multiple customized grades for use in different industries, including automotive and e-mobility. The current portfolio targets a family of unreinforced and up to 50% glass filled PA66, PA6 and PA66/PA6 grades with various levels of heat stabilization and impact modification as well as UL94 V0 flammability ratings. In compound testing, for instance, final grades with 25% recycled content have shown excellent tensile strength retention comparable to that of virgin Vydyne® PA66.

OEMs and tier manufacturers can depend on Ascend’s supply security thanks to an acquisition the company made last year.

Our feedstocks are reliable and consistent thanks to our majority purchase of Circular Polymers by Ascend, a post-consumer carpet recycler. We transform post-consumer carpets back into clean, consistent polymer feedstock for ReDefyne and other lines, which can serve as a role model for setting up or supporting similar circular economy operations for the automotive industry.

The recycled content in ReDefyne PA grades is certified by SCS Global in compliance with ISO 14021, and the materials’ carbon footprint is measured using Sphera’s Life Cycle Analysis tool.

Ascend’s team of scientists, engineers and application developers can work with automakers to streamline their transition to the new regulations without sacrificing quality or performance.

We work directly with OEMs and Tier manufacturers to deliver exactly what the brand wants and needs. With our security of supply and years of application development experience, we can help this transition to compliance go smoothly and successfully.

Sign up to receive our latest news and information about upcoming events