by Chris Guthrie

Chris manages the global cable ties and fasteners segment for Ascend.

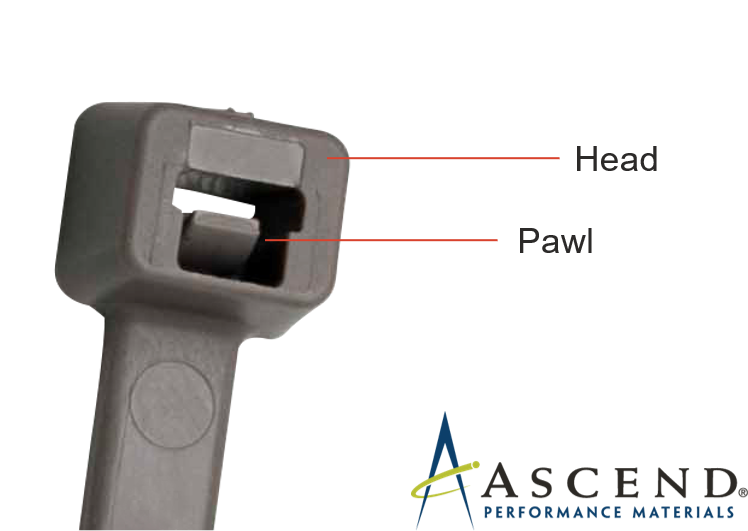

Cable ties, or zip ties, have three main sections: a head, a tail and a pawl. During installation the tail is inserted into the head where the pawl ratchets to allow the tail through one direction but hold firm on the other. The pawl is perhaps the most critical component in a cable tie.

It’s common to think the teeth on the tail are preventing a cable tie from releasing. What actually holds the zip tie in position is the pawl pushing up and creating pressure between the head and tail.

The pawl has to walk an incredibly tight line of being flexible enough to allow the tail to pass through the head and be stiff enough to hold its position within the teeth when the cable tie is under load. The force exerted on a cable tie under load is commonly referred to as the tensile strength and is a critical performance criterion.

Cable ties are tested in compliance with U.S. Military Specification and Standards, MIL-S-23190E. These ties must hold under constant strain at their design conditions to prevent failure or injury. When failures do occur, over 80% of the time it is due to the pawl releasing, not the cable tie breaking. As such, the design and performance of the pawl is essential.

Dozens of patents exist on cable tie pawl and head designs. Designs have to take into account many environmental factors including the heat the application is involved in, the amount of moisture uptake the material will have at equilibrium and even potential exposure to chemicals or UV light. These factors impact the performance of the pawl and can lead to stress cracking, degradation and failure.

For these reasons, material and tooling selection for the design are vital. The tool itself can cost upwards of 35% of the total machine cost. Given the incredibly tight (fractions of a millimeter) design clearance required, the materials and tooling work together to produce and reproduce millions of cable ties that perform without fault over years of use.

As the only performance plastics producer with a dedicated cable tie design team, Ascend helps cable tie producers troubleshoot some of the most common design issues with fasteners. Our full portfolio of engineered plastics offers excellent flexibility while maintaining tensile strength and processability, helping reduce failures and stand up to environmental challenges.

Sign up to receive our latest news and information about upcoming events